In today’s packaging industry, industrial machines for trays play a vital role in producing durable, eco-friendly, and cost-effective packaging products. These machines are widely used to manufacture various types of trays — from egg trays and cup carriers to industrial packaging trays for electronics and consumer goods. With the growing demand for sustainable packaging, molded pulp tray machines have become an ideal choice for manufacturers around the world.

1. Overview of Industrial Tray Making Machines

Industrial tray machines are designed to convert waste paper or natural plant fibers into molded pulp trays through a fully automated production process. The typical system includes several key sections:

Pulping System: Waste paper, cardboard, or plant fibers (such as bagasse or bamboo pulp) are mixed with water and refined into pulp.

Forming System: The pulp is vacuum-formed into specific tray shapes using precision molds.

Drying System: Formed trays are dried using metal drying lines, brick drying chambers, or natural sunlight.

Hot Pressing System (optional): Improves surface smoothness, rigidity, and appearance for high-end trays.

Automatic Stacking & Packing System: Completed trays are counted, stacked, and prepared for packaging and shipment.

2. Types of Industrial Tray Machines

Industrial tray production lines can be categorized into different types based on their structure and production scale:

Rotary Pulp Molding Machines: Designed for large-scale continuous production of trays such as egg trays, fruit trays, and cup holders. These machines provide high efficiency and stable operation.

Reciprocating Molding Machines: Ideal for medium-scale production, featuring flexible mold changing and energy-efficient performance.

Thermoforming Machines for High-End Trays: Used to produce biodegradable tableware and precision industrial trays, combining molding and hot-pressing for superior product quality.

3. Key Features and Advantages

Modern industrial tray machines are equipped with PLC control systems, automatic pulp supply, and precision molds, ensuring consistent quality and efficient production. The main advantages include:

Eco-friendly Production: Uses recycled paper or plant fibers, reducing plastic waste.

Cost Efficiency: Low raw material cost and high production output.

Versatile Applications: Suitable for packaging in food service, electronics, and consumer goods industries.

High Automation: Reduces labor cost through automated control, drying, and stacking systems.

Customization: Molds can be designed according to customer requirements to produce trays of various shapes and sizes.

4. Applications Across Industries

Industrial tray machines are used in multiple sectors:

Food & Beverage Industry: Cup carriers, food trays, fruit trays, and biodegradable tableware.

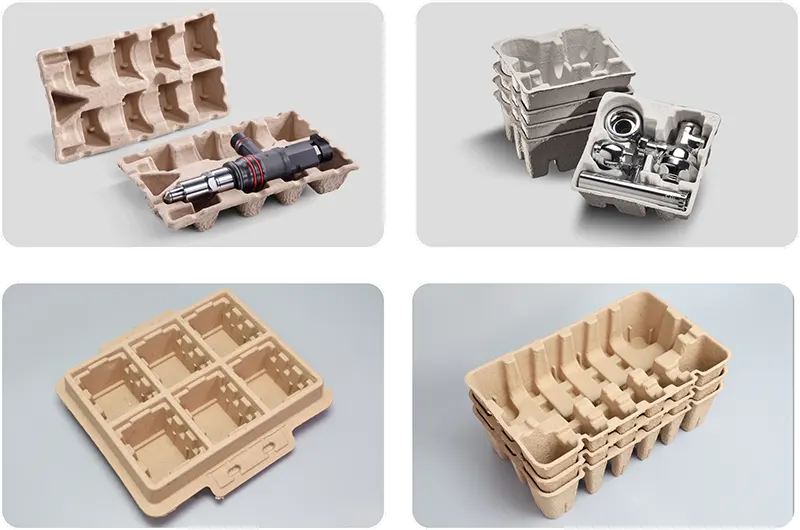

Electronics & Consumer Goods: Shockproof molded pulp trays for appliances, tools, and accessories.

Agriculture & Poultry: Egg trays, egg boxes, and seedling trays.

Medical & Industrial Packaging: Custom trays designed for protective transport of instruments and components.

HGHY: A Leading Manufacturer of Pulp Molding Machines

HGHY is a renowned name in the field of pulp molding machinery. With a reputation for innovation and quality, HGHY offers a range of machines suitable for various applications, including egg box production. Their machines are characterized by:

– Advanced Technology: HGHY machines incorporate cutting-edge technology, ensuring efficiency and precision in production.

– Customization Options: HGHY provides tailored solutions to meet specific production requirements, from small-scale operations to large-scale industrial setups.

– Environmentally Friendly: HGHY’s machines are designed with sustainability in mind, utilizing recycled materials and minimizing waste.

Industrial machines for trays represent a smart investment in sustainable manufacturing. They transform recycled materials into high-value packaging products that serve diverse markets — combining environmental responsibility with business profitability. With modern automation, flexible design, and proven reliability, these machines stand as a cornerstone of the green packaging revolution.