With global environmental regulations tightening and “plastic bans” spreading worldwide, one question becomes urgent: How long can plastic egg trays survive in the market? The answer is clear — the future belongs to sustainable, biodegradable pulp egg trays. For companies still running plastic production lines, shifting to pulp egg tray production is no longer optional; it’s a necessary step toward long-term growth.

The Challenges of Transformation

Transitioning from plastic to pulp is not without obstacles:

Equipment Gap: Plastic lines rely on injection molding or thermoforming, while pulp production requires pulping, molding, drying, and hot pressing systems. Most existing plastic equipment cannot be reused.

Raw Material Shift: Plastics depend on petrochemicals, while pulp molding uses recycled paper, cardboard, or agricultural fibers like bagasse. This demands new sourcing and material preparation expertise.

Technical Barriers: Pulp molding involves vacuum forming, slurry concentration control, and precise drying parameters. Skilled technicians and operator training are essential.

Investment Pressure: New equipment requires significant capital, and during the transition period, companies must balance old customers with new market development.

Quality Control: Pulp products are more sensitive to raw material variations and process settings, making strict QC procedures critical.

These challenges are real — but they also mean that those who overcome them first will secure a powerful advantage in a rapidly changing market.

The Benefits of Switching to Pulp

Despite the hurdles, the rewards are compelling:

Policy Alignment: Single-use plastics are being restricted or banned worldwide, while pulp products are biodegradable and fully compliant with environmental regulations.

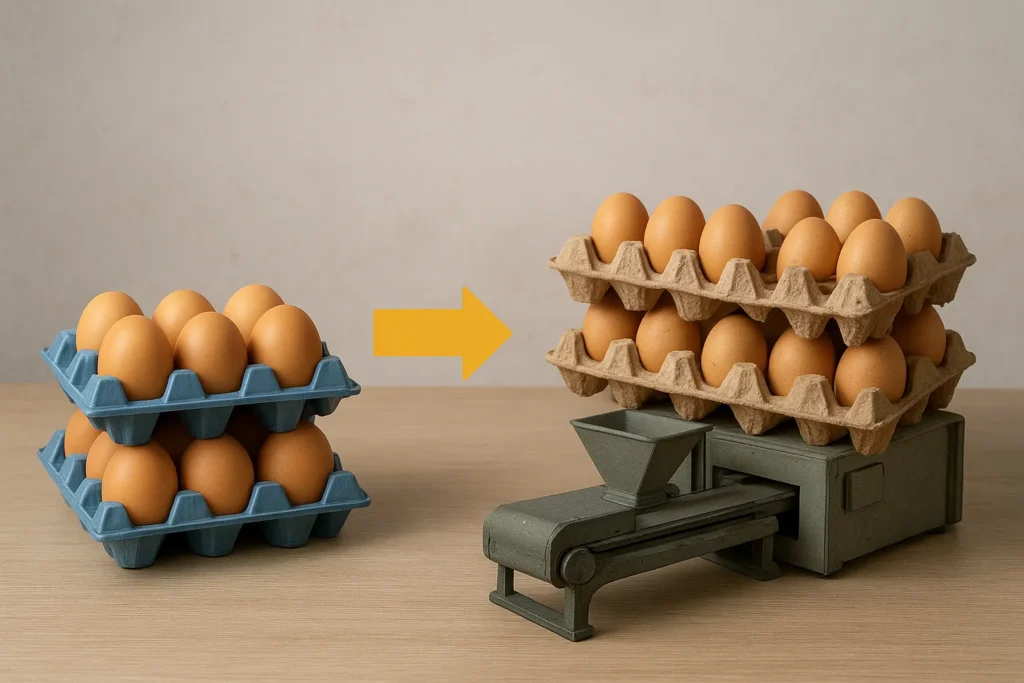

Rapidly Growing Demand: From egg trays and cup carriers to food packaging and industrial cushioning, pulp molded products are seeing explosive global demand.

Lower Raw Material Costs: Recycled paper, crop residues, and bagasse are inexpensive and renewable, insulating businesses from oil price volatility.

Higher Product Value: Eco-friendly pulp trays not only meet regulations but also enhance customer brands, often commanding higher market prices than plastic.

Sustainable Brand Image: Transitioning to pulp production positions your company as a forward-looking, environmentally responsible partner.

Our Solution

For companies considering this critical shift, our Pulp Egg Tray Production Lines provide the complete solution:

- Full range of systems, from pilot-scale to fully automated high-capacity lines.

- Integrated pulping, molding, drying, and hot-pressing systems.

- Flexible raw material options: recycled paper, cardboard, agricultural fibers.

- Comprehensive training and technical support to ensure a smooth transition.

- Energy-efficient design for reduced operating costs.

The path to transformation may seem challenging, but the opportunities far outweigh the risks. By adopting pulp egg tray production, you are not just upgrading your equipment — you are upgrading your future.

HGHY: A Leading Manufacturer of Pulp Molding Machines

HGHY is a renowned name in the field of pulp molding machinery. With a reputation for innovation and quality, HGHY offers a range of machines suitable for various applications, including egg box production. Their machines are characterized by:

– Advanced Technology: HGHY machines incorporate cutting-edge technology, ensuring efficiency and precision in production.

– Customization Options: HGHY provides tailored solutions to meet specific production requirements, from small-scale operations to large-scale industrial setups.

– Environmentally Friendly: HGHY’s machines are designed with sustainability in mind, utilizing recycled materials and minimizing waste.

The Molded Pulp Insert Machine is more than equipment—it’s a gateway to joining the supply chain of the world’s leading smartphone brands. With a production capacity of 650–800 kg per day, rapid ROI, and compliance with global eco-packaging regulations, it positions manufacturers at the forefront of a booming, future-proof industry.

As Apple, Samsung, and other high-end electronics brands continue to expand sustainable practices, the companies that invest in molded pulp packaging today will secure not only business growth but also a role in shaping the green industrial ecosystem of tomorrow.