In the premium smartphone industry, packaging is more than a protective shell—it’s an extension of brand identity. Companies like Apple and Samsung have already set the benchmark by transitioning their smartphone boxes and internal inserts from traditional plastic to molded pulp solutions. This shift not only enhances sustainability credentials but also redefines the packaging supply chain on a global scale.

The Shift Toward Sustainable Smartphone Packaging

In recent years, both Apple and Samsung have eliminated plastic trays in their phone boxes, replacing them with molded pulp inserts made from renewable fibers. This change responds to global plastic bans, consumer expectations for eco-friendly products, and the brands’ own environmental pledges.

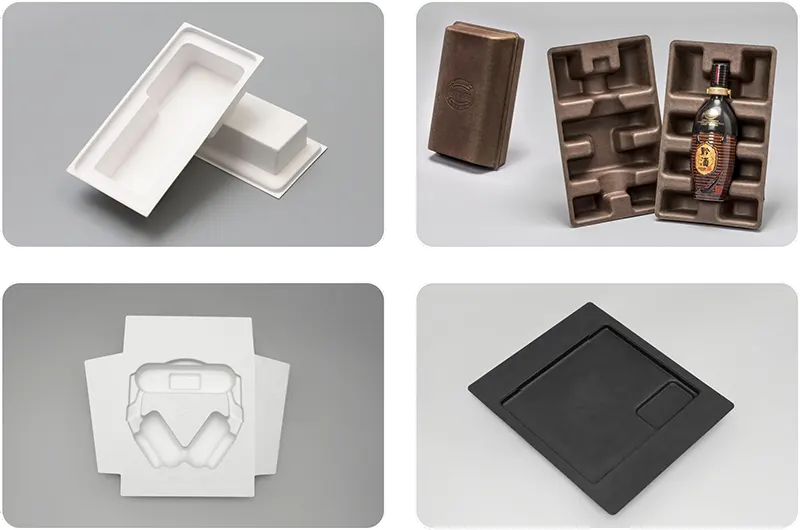

The Molded Pulp Insert Machine plays a key role in this transformation, producing high-precision, premium-quality inserts tailored for smartphones and accessories. These inserts combine:

Perfect Fit & Protection – Custom molds ensure phones and components are safely secured.

Premium Aesthetics – Smooth finishes and clean designs that reflect luxury branding.

Eco-Friendly Materials – Derived from wood pulp, sugarcane bagasse, or bamboo fiber, fully recyclable and biodegradable.

Molded Pulp Insert Machine

The machine converts wood pulp, sugarcane bagasse, and bamboo fiber into high-quality molded pulp inserts. It is mainly used to produce protective inserts for electronics, industrial shockproof trays, and premium cosmetic packaging.

Industrial Relocation and Supply Chain Opportunities

As production bases shift to regions with lower costs and strong industrial ecosystems, the demand for localized molded pulp packaging manufacturing is surging. Smartphone giants transferring assembly lines to Asia, Eastern Europe, and beyond have driven an accompanying migration of packaging suppliers.

For investors and manufacturers, this creates opportunities to:

Integrate into Global Supply Chains – Becoming certified suppliers for major electronics brands.

Build Regional Hubs – Establish production near assembly plants to reduce logistics costs and response times.

Stimulate Peripheral Industries – Driving demand for mold design, automation equipment, printing, and finishing services.

Driving Value Across the Ecosystem

The adoption of molded pulp inserts in smartphone packaging doesn’t just benefit brand image—it transforms the surrounding industrial chain.

Raw Materials – Boosts demand for recycled paper, bamboo pulp, and bagasse fiber.

Machinery & Technology – Expands markets for pulp molding machines, hot-press systems, and automation lines.

Design & Customization – Creates opportunities for high-value design studios specializing in premium eco-packaging.

HGHY: A Leading Manufacturer of Pulp Molding Machines

HGHY is a renowned name in the field of pulp molding machinery. With a reputation for innovation and quality, HGHY offers a range of machines suitable for various applications, including egg box production. Their machines are characterized by:

– Advanced Technology: HGHY machines incorporate cutting-edge technology, ensuring efficiency and precision in production.

– Customization Options: HGHY provides tailored solutions to meet specific production requirements, from small-scale operations to large-scale industrial setups.

– Environmentally Friendly: HGHY’s machines are designed with sustainability in mind, utilizing recycled materials and minimizing waste.

The Molded Pulp Insert Machine is more than equipment—it’s a gateway to joining the supply chain of the world’s leading smartphone brands. With a production capacity of 650–800 kg per day, rapid ROI, and compliance with global eco-packaging regulations, it positions manufacturers at the forefront of a booming, future-proof industry.

As Apple, Samsung, and other high-end electronics brands continue to expand sustainable practices, the companies that invest in molded pulp packaging today will secure not only business growth but also a role in shaping the green industrial ecosystem of tomorrow.