Molded Pulp Insert Machine

Innovation, sustainability, and brand responsibility

Multiple patented tech ensure high precision, efficient and stable running.

- High Return on Investment

- Scalable for Growth

- Eco-Friendly Solution

Main Features

- Optimized for Premium Small-Batch Runs

- Dual-Layer Build Ensures Simple Maintenance

- Space-Saving Design with Exceptional Efficiency

- Streamlined Mold Area for Faster Changeovers

Technical Parameters

| Model | ZJFD—7050 | ZJWD – 7050 |

|---|---|---|

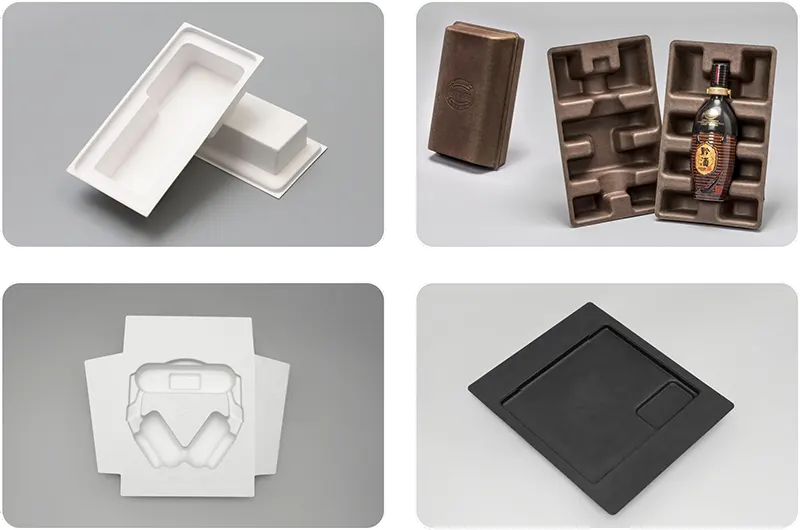

| Product Application | Inner Lining Packaging is Increasingly the Preferred Choice for 3C Digital Products, Cultural and Creative Products, Premium Gift Boxes, Cosmetics, and More. | |

| Daily Capacity | Base On Products | |

| Platen Size | 700 × 500 mm | |

| Heating Energy | Electricity / Thermal Oil | |

| Forming Method | Flip Type | Reciprocating |

| Hotpress Method / Pressure | Hydraulic System / Max 20 Tons Pressure | |

| Safety Protection | Self-locking & Auto-stop Design | |

| Max Product Height / Thickness | 120 mm / 1.2 mm | |

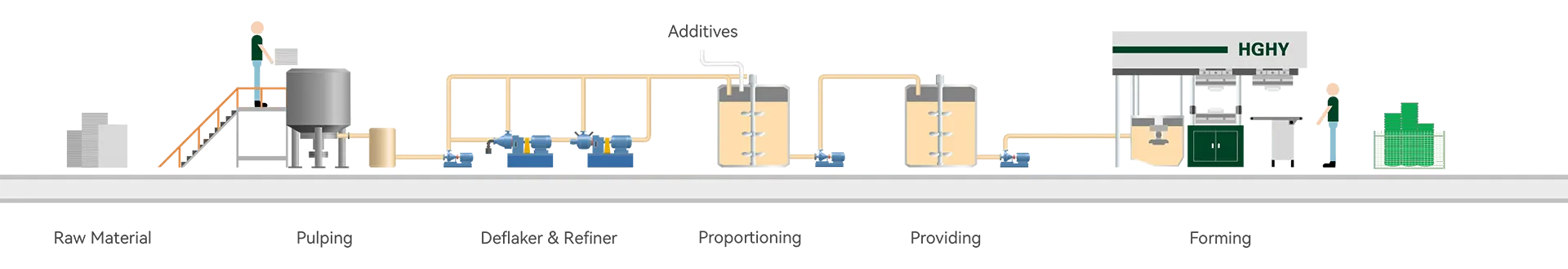

Production Process

HGHY Molded Pulp Insert Machine is composed of pulping system, multiple sets of main system (including forming, hotpressing, trimming, stacking and robot), auxiliary system, making pulp molded tableware and food packagings.

Applications

Raw Material

Bagasse Pulp

Bagasse is a by-product of sugar mills and a typical raw material for paper fiber. The average fiber length is 1.47-3.04mm, and the fiber length of bagasse is 1.0-2.34mm. It has the advantages of moderate strength and moderate toughness. It is currently the most suitable raw material for pulp molding products. Currently, sugarcane is mostly used in lunch boxes and tableware products. Molded Pulp Insert Machine utilizes this slag fiber as a primary input for crafting paper trays. Additionally, some high-end mobile phone holders and cosmetic packaging also utilize this raw material, demonstrating its versatility and sustainability.

Bamboo Pulp

The process of creating paper trays involves using a Molded Pulp Insert Machine. Bamboo serves as an excellent choice for this purpose due to its remarkable properties. Bamboo is an incredibly fast-regenerating raw material, making it highly sustainable and environmentally friendly. Moreover, it is odorless, naturally antibacterial, antimicrobial, and hypoallergenic.

Wood Pulp

Molded Pulp Insert Machine falls under the category of machinery used in the production of paper trays. Wood pulp is pulp made from wood. According to pulping materials, pulping methods, and pulp uses, etc., it can be roughly divided into two categories: coniferous wood and hardwood. Molded Pulp Insert Machine plays a crucial role in the process of transforming wood pulp into functional and sustainable paper trays.

Frequently Asked Questions

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

The rate of return is high, and it usually pays back in 2-3 years.

HGHY has helped more than 300 clients in over 60 countries setting up their plants with leading capacity and superior quality production.

Reviews

There are no reviews yet.